Seismic Testing of 3D Printed Small Scale Masonry

Even though Masonry is one of the oldest building materials, our understanding of its behavior at the level of the structure (system level) is limited. Therefore, there is a need for extended shake table testing. But shake table tests are expensive and full-scale system-level testing of large buildings is only possible in a handful of shake tables in the globe – and at a huge cost.

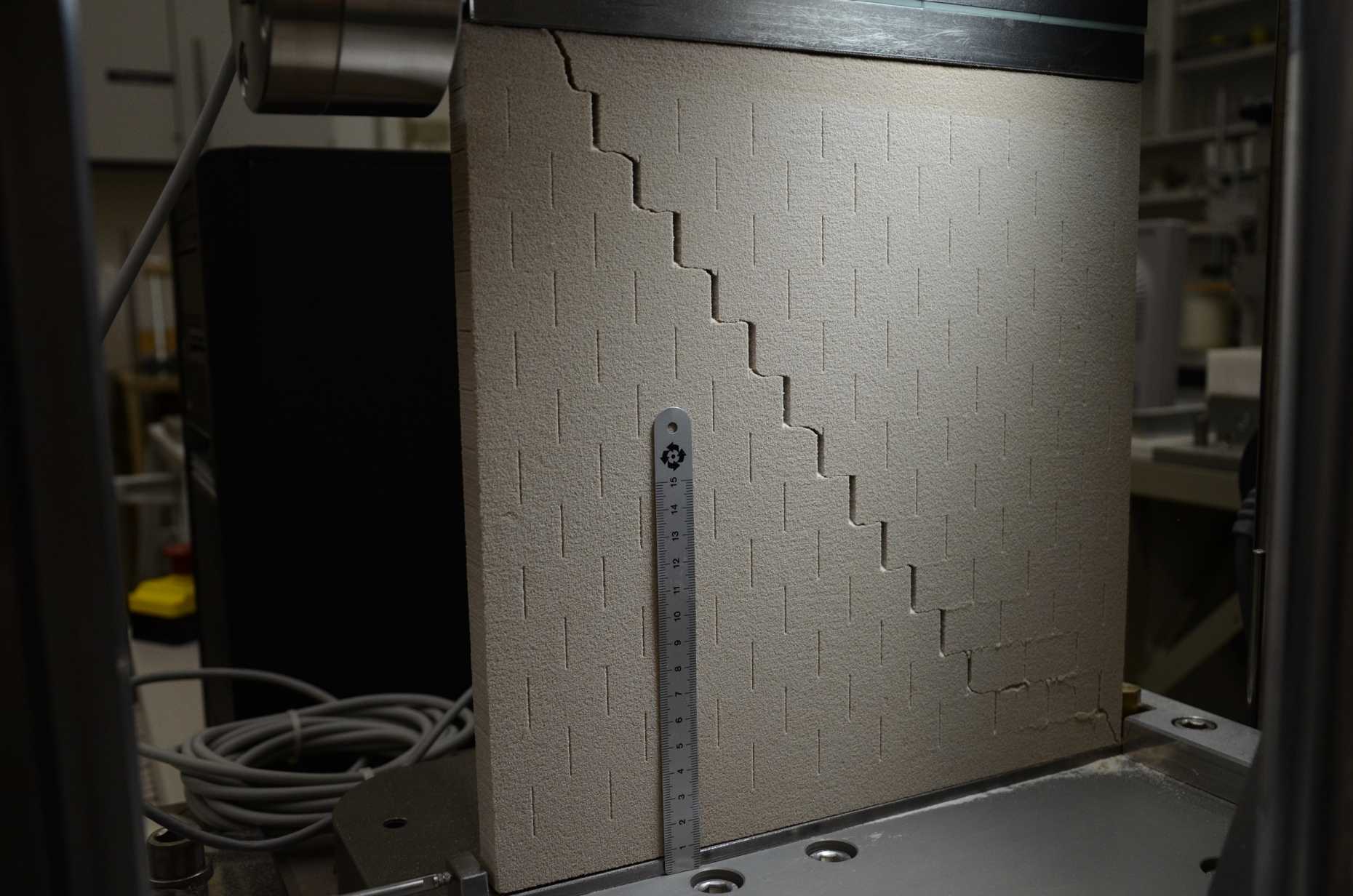

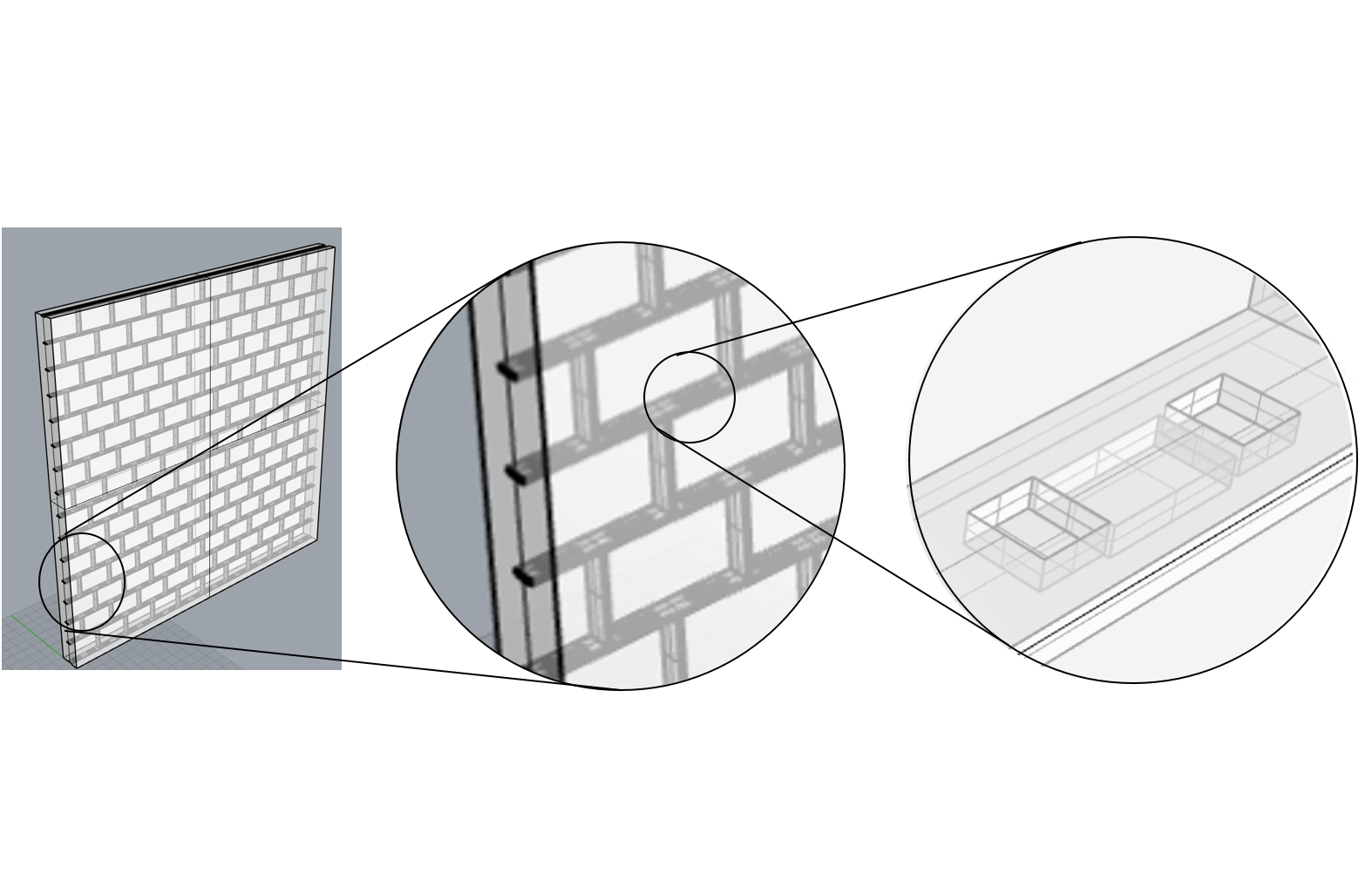

We propose to take advantage of research developments in 3D printing and develop a method to perform system-level testing at a small scale using 3D printers and a geotechnical centrifuge (to preserve similitude). The key is to print materials with behavior controllable and similar to masonry. We aim at controlling the properties of 3D printed models via controlling the geometry of a 3D printed “meta”-mortar. The method will be developed via typical static masonry tests performed on the 3D printed parts. Then shaking table tests (in a centrifuge) of miniature structures will be performed. The cost of the dynamic tests is expected to be so low, that multiple tests can be performed, so that existing numerical methods can be validated in the statistical sense. Such a statistical validation can show whether simple masonry models are "good enough", in the sense of being able to predict the statistics of the response to a set of design ground motions, even though they cannot predict the response to an individual excitation.

With the rapid evolution of 3D printing, it could be possible to scale-up the methods developed in this project, so that other Civil Engineering materials can be tested faster and cheaper than now. This is a game changer in structural testing, as it will enable researchers to test structures that up to now it was impossible or very expensive to test at a system level.

Funding: ERC Starting Grant 803908 (PI: Michalis Vassiliou)

Duration: 1.4.2019 - 31.3.2024

PhD Students: Lorenzo Del Giudice and Antonios Katsamakas